Equipment Overview

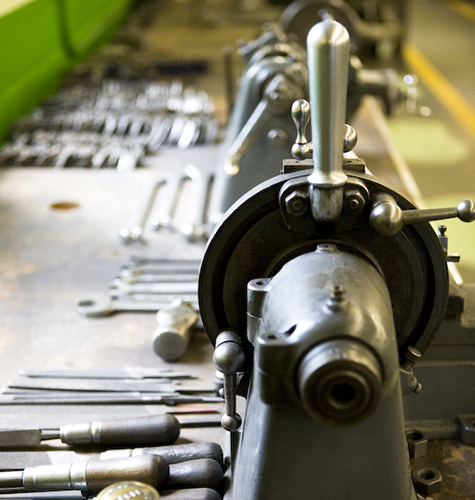

Primary Equipment

- 20 CNC Swiss Machining Centers with Automatic Bar Feeders up to 1.500″ diameter

- 150 Swiss Type Automatic Lathes with up to 1.250″ diameter capacity. More than 90 with Spindle Stopping Devices for milling and cross-drilling operations during machining cycle

- 2 Large Centerless Grinders for preparing bars and rods to exact tolerance prior to machining

- 55 Escomatic coil feed machines from .020″ to .250″ diameter capacity

Secondary Equipment

- Multiple centerless parts grinders, both thru-fed and plunge-type

- 30 slotting machines

- 25 Hartford & Tesker Roll Threading machines

- 6 Gear Hobbing machines

- Multiple single and double-head milling machines

- 1 Multi-spindle tapping machine

- 7 multiple-operation rotary tables

- Various vibratory & tumbling equipment for part finishing operations

Support

- Comprehensive Toolroom Support Equipment

- Computerized Machining Specific Statistical Process Control (SPC) System

- Computer Aided Design (CAD) for tools

- Computerized CAM Cutting

- Computerized Paperless Calibration System

- Computerized Bar Coding System

- Electronic Weigh Scales

- Note: Additional equipment used for in-process quality assurance, tool sharpening and support operations is not listed.